Swedesim AB provides systems for processing food waste in the food production/processing industry. Through our solutions we offer efficient and robust systems for managing the waste and to preserve its value as an asset as biogas substrate.

‘ECO Waste Away’ (EWA) is a product family, consisting of ‘EWA Maxi’, ‘EWA Midi’ and ‘EWA Mini’, developed by Swedesim AB together with Diskomat AB. Swedesim has through its suppliers been delivering to Diskomat. Diskomat is a company planning and installing complete systems for dishwashing, cleaning and waste management (www.diskomat.se). Its customers are restaurants, hospitals, flight catering kitchens, schools, canteens and other large caterers.

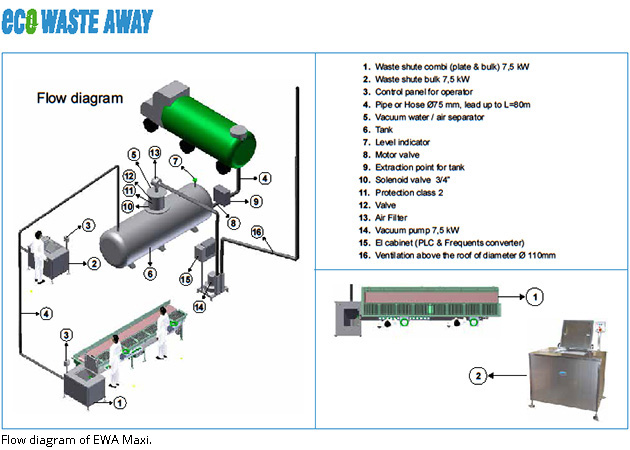

EWA Maxi is a robust and reliable system equipped with a powerful mill with impressive capacity which can manage all types of food waste material, including marrowbone. The processing technique provides a preserved waste product, optimal as biogas substrate. The processed waste material is transported through pipes by a vacuum pump to a vacuum tank. A level indicator tells when the tank is about to get full and a suction vehicle can come emptying it and transport the waste material to a biogas facility.

The smaller waste disposal systems, named ‘EWA Midi’ and ‘EWA Mini’, are suitable for handling food waste of smaller volumes. Visit www.diskomat.com for more information.

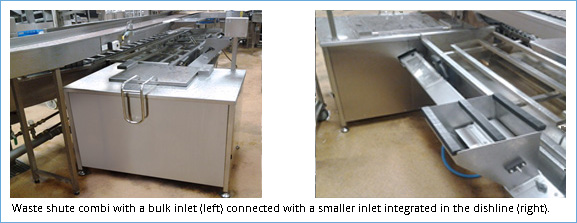

Below is shown a flow diagram of the EWA Maxi system in its basic execution with 1. Waste shute combi and 2. Waste shute bulk. The waste shute bulk is customized for bulks, whole canteens. The combi variant consists of a bulk inlet, but is also integrated in the dishline with a transport screw moving the food waste from a number of smaller inlets, customized for scraping plates, to the mill. The system can be adapted in many ways, such as many inlets of various types connected to the same tank.

The processing technique in EWA Maxi, transporting the grinded waste material in a closed system by vaccum to a vacuum tank, provides a preserved substrate ideal for biogas production. This together with the high capacity and capability of grinding all types of food waste – and with a proved reliability, makes it well suited in industrial food production/processing. Not to mention all the variations and adaptations of the system that can be made. For this reason Swedesim and Diskomat have split focus, with Diskomat focusing on their existing markets and Swedesim focusing on applications for the industrial food production/processing.