Based on the EWA Maxi system different variations and applications can be made to fit the needs for various industrial processes:

- Possibility of various transport solutions of the waste material to the inlet(s).

- Possibility of different variations of inlets.

- Possibility of multiple inlets and long lines.

- Possibility of connected storage tanks, either in vacuum or atmospheric pressure.

- If water is used in the process – possibility of dewatering systems either before the mill or in connection to tank.

Further strengths with the EWA Maxi system for handling food waste and preserve the value of the waste material, i.e. making it optimal for biogas production:

- Rugged, robust mill with wear parts made of Hardox and other parts of SS2348 (stainless) that can handle all types of food waste, including marrowbone.

- High capacity; from 1500 L/h with batch run to 5000 L/h with continuous run.

- Provides small pieces (~8 mm width).

- No need to add water, except for cleaning or if the waste material is too vicious for collection by suction vehicle.

- Very little stirring in the waste material (compare with transport by fluid pumps).

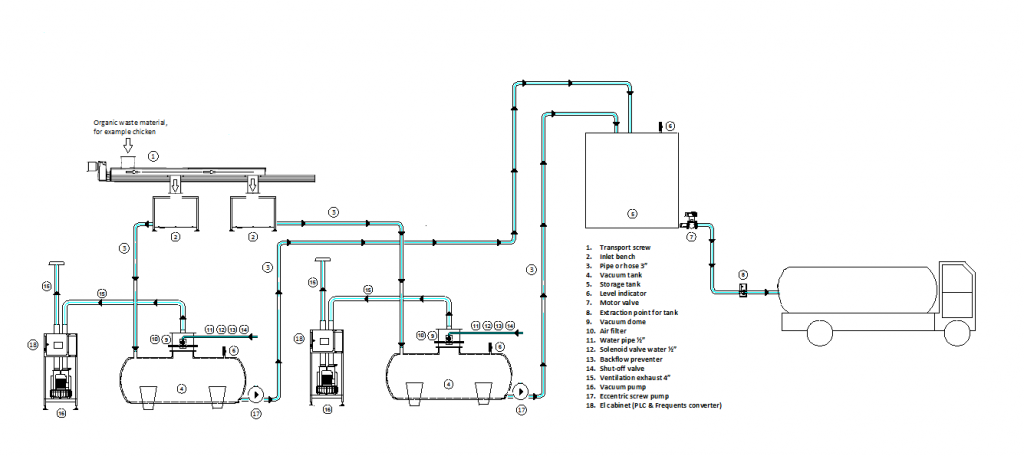

Below is shown a system based on the EWA Maxi system but with some adaptations, making it suitable for large volumes of i.e. chicken waste material. With the two mills in continuous run this system can process 5-10 tons of waste material per hour. An eccentric screw pump from each vacuum tank can pump the waste material to storage tank(s) of basically unlimited size.

We have continuous close contact with our suppliers since our years of delivering EWA Maxi to Diskomat. We are able to deliver custom-made systems, adapted for the unique industrial process. Diskomat will, with its long experience and adequate knowledge, answer for installation and service of the systems.

The President of Swedesim, Göran Johansson, has a solid technical background with emphasis on product and software development, as well as more than 25 years of executive experience in international business. Göran’s son, Staffan Johansson, is MSc in Biology with knowledge and experience in the biogas field.

We would very much like to meet you.